By NIKE

By NIKE

Matthew Nurse and the Nike Sport Research team provide an inside look at the high-tech research facilities inside the lab at Nike’s World Headquarters, shedding light on how they turn data into innovation for athletes everywhere.

How was Nike’s sport research lab formed?

The research lab was started in Nike’s infancy, in 1980 in Exeter, N.H. It was formed in response to the running boom of the late ‘70s (the name was coined by recent hire Mark Parker, current NIKE, Inc. President and CEO). The primary goal was to understand runners’ needs in order to make the best products for athletes.

What exactly do you do in the lab?

We quantify athletes’ movements, the environments they play in and the products they use. Then we analyze the results and if we are able, use that knowledge to make really unbelievable product.

What is the process of working with athletes?

Nike’s sport research lab is a destination for athletes when they visit Nike’s Oregon campus. We might solve a problem they have or help with a performance issue, but the really cool thing is making them part of the process. They contribute performance insights through testing and data, and provide verbal feedback that actually drives our product forward. Generally, what we learn from working with elite athletes, can be used to make better product for everybody. In cases where considerations for elite athlete don’t apply to everyday athlete, we make sure that we are also working with athletes of all skills and abilities.

What do you typically hear from athletes?

If you look at how sport has evolved over the last 30 to 40 years, athletes are getting stronger and faster — there’s no question. But the three basic things athletes ask haven’t changed in decades: make me better, protect me and inform me.

How far in advance are you working on product?

We can work on anything from 18 months in advance to decades out. Often, we’re doing research and collecting data that informs a specific technology or a wide range of products, not just a single shoe or garment.

When you work that far in advance, what is it like to see the final product?

What really motivates us is when we see our products being used on the field of play, whether its at a pinnacle event like the Olympics or the World Cup, or just seeing someone out on a run. We obsess the details. We stare at their feet, and if they are in a motion-controlled shoe and it looks like they are pronating too much, we worry about those things. If we go to a soccer game and an athlete slips, we obsess over that and we come in the next morning and everybody’s asking each other “Hey, did you see that person slipping?” We start to question why did that happen, what are we doing wrong, and how do we make it better.

So it’s not all about the data?

We collect a lot of data, an unbelievable amount of data. But by itself, data is useless until you turn it into knowledge. And the knowledge that we gain from each project and each athlete helps us better understand the product at hand. The long-term benefit of having a sport research lab like ours since 1980 is a wealth of information to build on.

How do you convert data into actual product features?

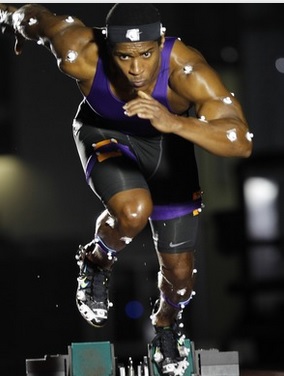

We can look at data from athletes about how they perform, how they move and how they fatigue; and we can look at data from product as it relates to fit, flexibility, traction and cushioning. However, the interaction between athletes and products is complex, and requires a lot of data to solve. Take motion capture for example. We put markers on athletes and we collect 200 frames per second and higher — so for one second, there is a minimum of 200 frames of information. And each one of those has three-dimensional coordinates from the athlete’s movements. Over the coarse of one particular study, we have, say, 10 subjects come in with two different shoes, or two different actions (running, jumping), and we end up with millions of data points that we need to capture and analyze. Then we take that information and drive product.

What are the benefits of testing in an environmental chamber?

We are able to very accurately control the temperature and humidity in the environmental chambers to determine how product will perform in an environment like Brasil, where there are extreme temperatures and humidity. So even though we are located in Beaverton Ore., which one might argue is always somewhat rainy and cool, we can accurately replicate weather from anywhere on the planet and make sure our product is going to work in those environments.

How often do you miss the mark in the lab?

Building knowledge can take a long time and we want to do it in a way that ensures the knowledge we generate is true. Failure can happen when we apply that knowledge. There are plenty of examples where we have a good solid understanding of a particular sport or an athletic attribute, and we make an educated hypothesis at what we think might make it better. We build some prototypes, and more often than not, they don’t make the athlete better. That is just part of the innovation process. We try and fail and try again and each time we fail, we have really good learnings and it always makes us want to try two other things after that.

So any innovation requires some trial and error?

Being a researcher isn’t just about science. It’s an extremely creative process in the sport research lab, because you are solving new problems and coming up with new ways to apply findings every single day. We want to provide the best product and the best experience for all of our athletes and consumers. In the end we are all made to move and if we can do something that helps us move a little better, be more protected and enjoy the experience along the way, that’s what we are going to do.

Disclaimer: Articles featured on Oregon Report are the creation, responsibility and opinion of the authoring individual or organization which is featured at the top of every article.